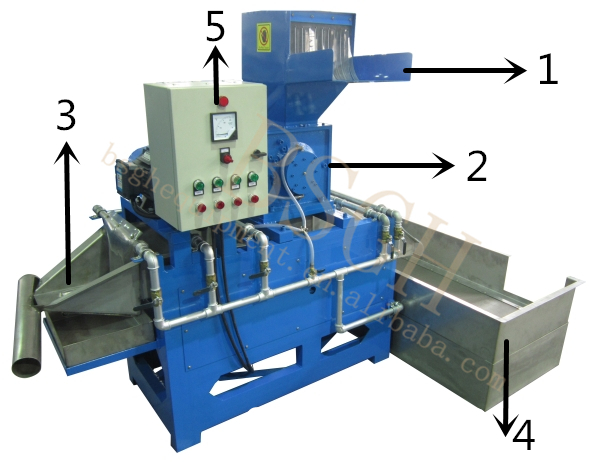

BS-10 Wet cable wire separator machine

Water recycling granulator machine Technical data :

Machine weight: 800KG

Power: 8.15KW

Voltage:110V,220V,380V,460V

Processing diameter: below 20mm

Machine size: L2700*W1400*H1800

Production: 60~120KG/H

1 : Hopper 2 : Crusher 3 : Vibration Table

4 : Water Pump 5 : Control Box

Wet cable wire crusher and separator machine Specification

1 : All of oil hole must be filled with mechanical butter before operation (once a week)

2 : The water tank must be filled with water

3 : Press the power buttons in the following sequence: water pump/segregating unit/grinder.

From the left to the right is :

Crusher – separator – water power unit - reserved

Feed water level regulation

1 : Adjust the water level according to the quantity of PVC/rubber particles and copper particles on

the separator plate.

2 : If there are more PVC/rubber particles in copper particles, the water level could be appropriately adjusted higher.

3 : If the PVC/rubber particles don’t go up with copper particles together, the water level could be

appropriately adjusted lower.

The way to replace the screen

1 : Replacing the screen is aimed to increase working efficiency, separating the PVC/rubber particles and copper particles completely.

2 : When replacing the screen, firstly, open the right cover of the grinder; then, loosen the screw of screen to remove it; finally, put the ideal screen into it.

3 : Replacing the screen according to the wire diameter (communication wire: Φ2-2.5mm;

electric wire: Φ2-2.5mm;other wire: Φ3-5mm)

4 : Adjustment of the screen: The ideal distance between the screen and the rotary cutter is about 1mm.

The way to sharpen knives of water granulator and separator machine

1 : Rotary cutter: Sharpen it by grinder and hold the blade at the ideal 15 degrees. ( No need to

remove the blade).

2 : Stationary knife: Sharp it by grinder or grinding machine after removing the stationary knife.

3 : Knife adjustment: The ideal distance between rotary cutter and stationary knife is about 0.2mm.

- Buy BS-10 Wet cable wire separator machine for sale,price,BS-10 Wet cable wire separator machine exporter/importer,suppliers,factory,manufacturers in China.

-

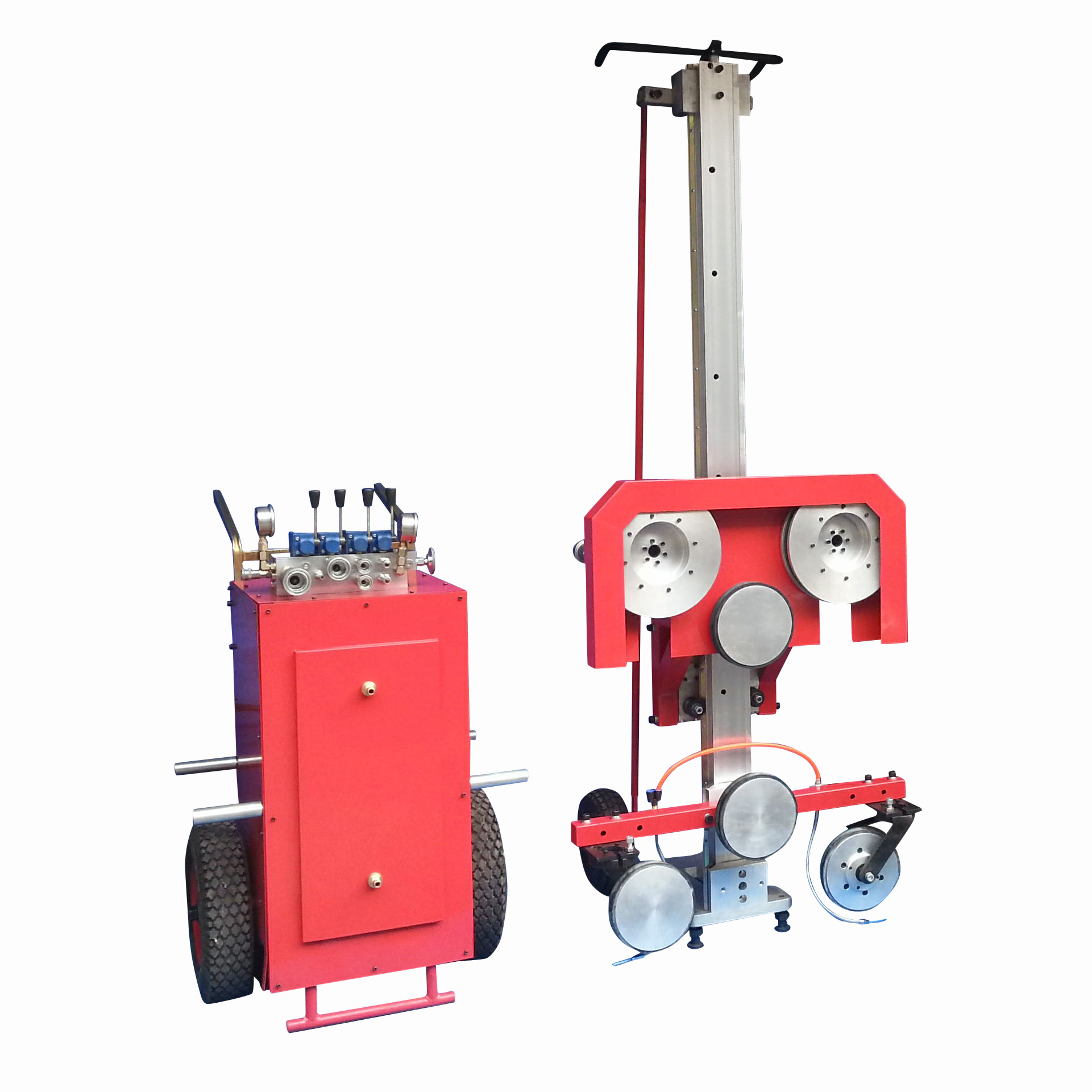

Popular betão Pedra divisora bs-hd90a hydrualic Da construção, ferramentas

Popular betão Pedra divisora bs-hd90a hydrualic Da construção, ferramentas

-

Sucata de máquina manual cable stripping bs-006

Sucata de máquina manual cable stripping bs-006

-

Automático de FIO máquina elétrica avançada utilizada (bs-013)

Automático de FIO máquina elétrica avançada utilizada (bs-013)

-

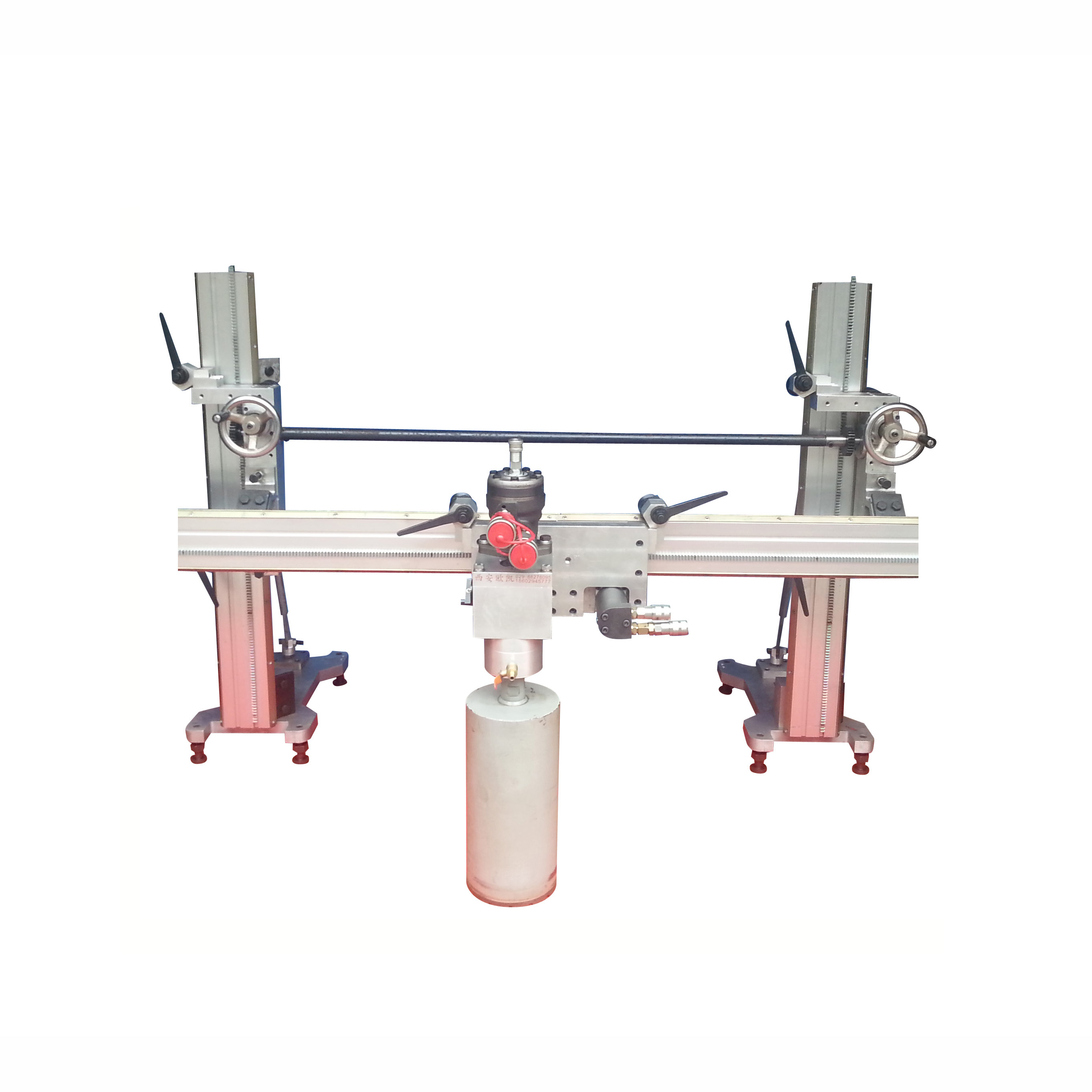

Dimond FIO máquina de Corte concreta bs-90am VIU

Dimond FIO máquina de Corte concreta bs-90am VIU

-

Dimond FIO máquina de Corte concreta 80am VIU

Dimond FIO máquina de Corte concreta 80am VIU

-

BS-10 wet cable wire separator machine

BS-10 wet cable wire separator machine

-

Unidade de potência elétrica

Unidade de potência elétrica

-

Electronic reciclagem de resíduos máquinas Mini bs-400

Electronic reciclagem de resíduos máquinas Mini bs-400

-

Diamond core perfuração concreto hidráulico máquina de Corte

Diamond core perfuração concreto hidráulico máquina de Corte

BS-40 Wet cable wire separator machine

BS-40 Wet cable wire separator machine

BS-20 Wet cable wire separator machine

BS-20 Wet cable wire separator machine

BS-05 Wet cable wire separator machine

BS-05 Wet cable wire separator machine

BS-800 manufacture gravity scrap copper pvc separation cable wire granulating recycling machine

BS-800 manufacture gravity scrap copper pvc separation cable wire granulating recycling machine

Wang Na

Wang Na